When a drone ascends to several hundred feet above the earth’s surface, it enters an environment where atmospheric filtration is significantly thinner than at ground level. For the human pilot, protection might come in the form of a bottle of SPF 50; however, for the drone’s camera system, “sunscreen” takes the form of advanced optical filters and chemical coatings. Understanding what is in this technological sunscreen is essential for any aerial cinematographer looking to preserve sensor longevity and ensure color accuracy in high-glare environments.

The Molecular Shield: Understanding UV Filter Composition

At the core of a drone’s optical protection system is the UV filter. While often used as a physical sacrificial layer to protect the lens from dust or impact, its primary chemical purpose is to block ultraviolet light. Ultraviolet radiation, specifically in the UV-A and UV-B spectrums, can cause significant “haze” in aerial images and, over time, can lead to the degradation of the organic dyes found in the Bayer filter array of a camera sensor.

The Role of Ultraviolet Radiation in High-Altitude Imaging

In the upper atmosphere, UV light is more pervasive. Unlike the human eye, which cannot see ultraviolet light, digital sensors are often sensitive to it. This sensitivity manifests as a blueish tint or a loss of contrast, particularly when shooting landscapes from a high vantage point. The “sunscreen” for the lens—the UV filter—contains specialized particles that absorb these wavelengths (typically those below 390 nanometers) while allowing the visible light spectrum to pass through untouched.

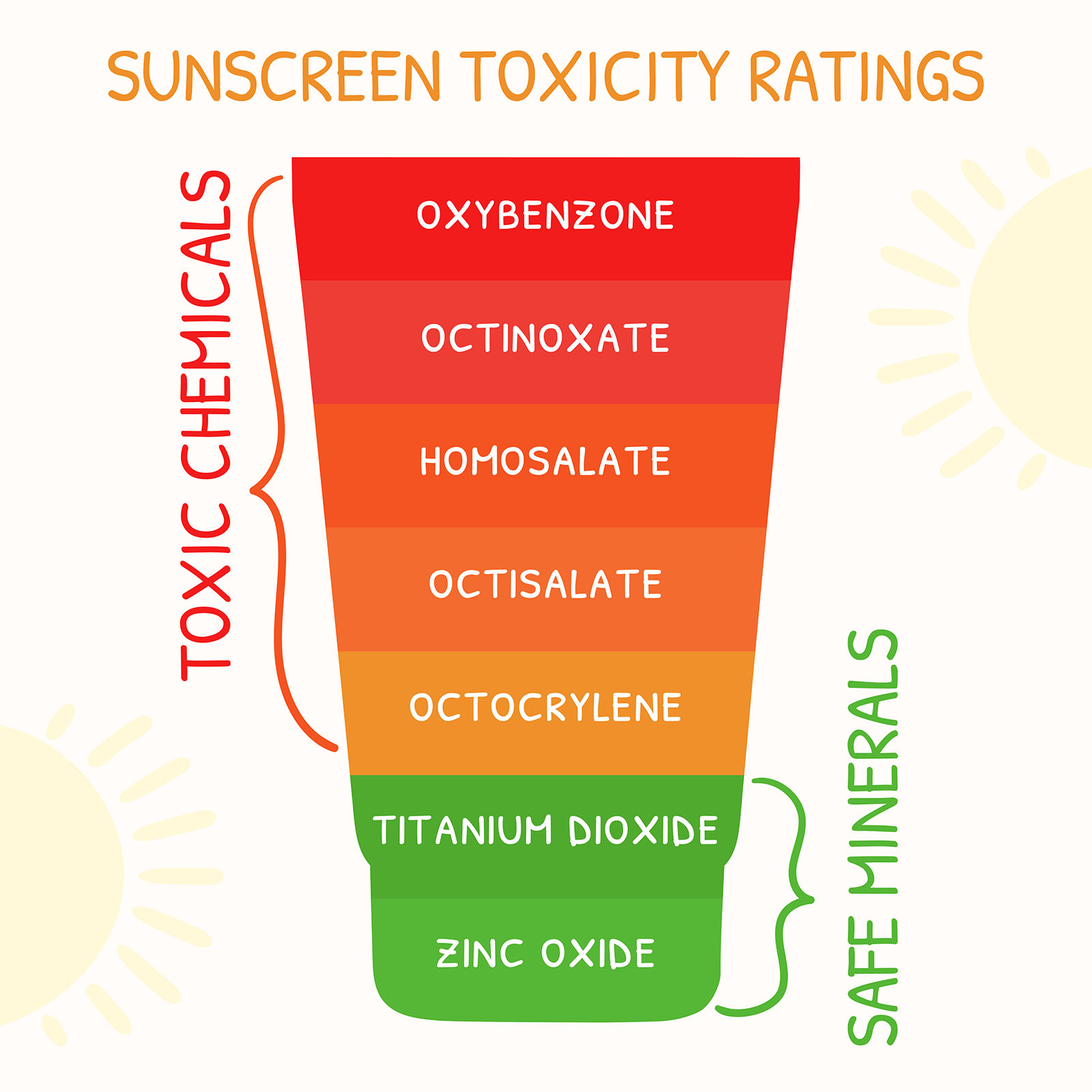

Chemical Composition: Multi-Resistant Coatings (MRC)

High-end drone filters are not just plain glass; they are treated with Multi-Resistant Coatings (MRC). These coatings consist of several microscopically thin layers of metallic oxides. Specifically, substances like Silicon Dioxide (SiO2) and Titanium Dioxide (TiO2) are vacuum-deposited onto the glass surface. These layers work through destructive interference to reduce reflections and prevent ghosting, much like how high-quality sunglasses manage light. By applying these “ingredients,” manufacturers ensure that the light hitting the sensor is pure, filtered, and free from the refractive noise caused by the sun’s direct rays.

The Ingredients of Clarity: Glass Quality and Refractive Indices

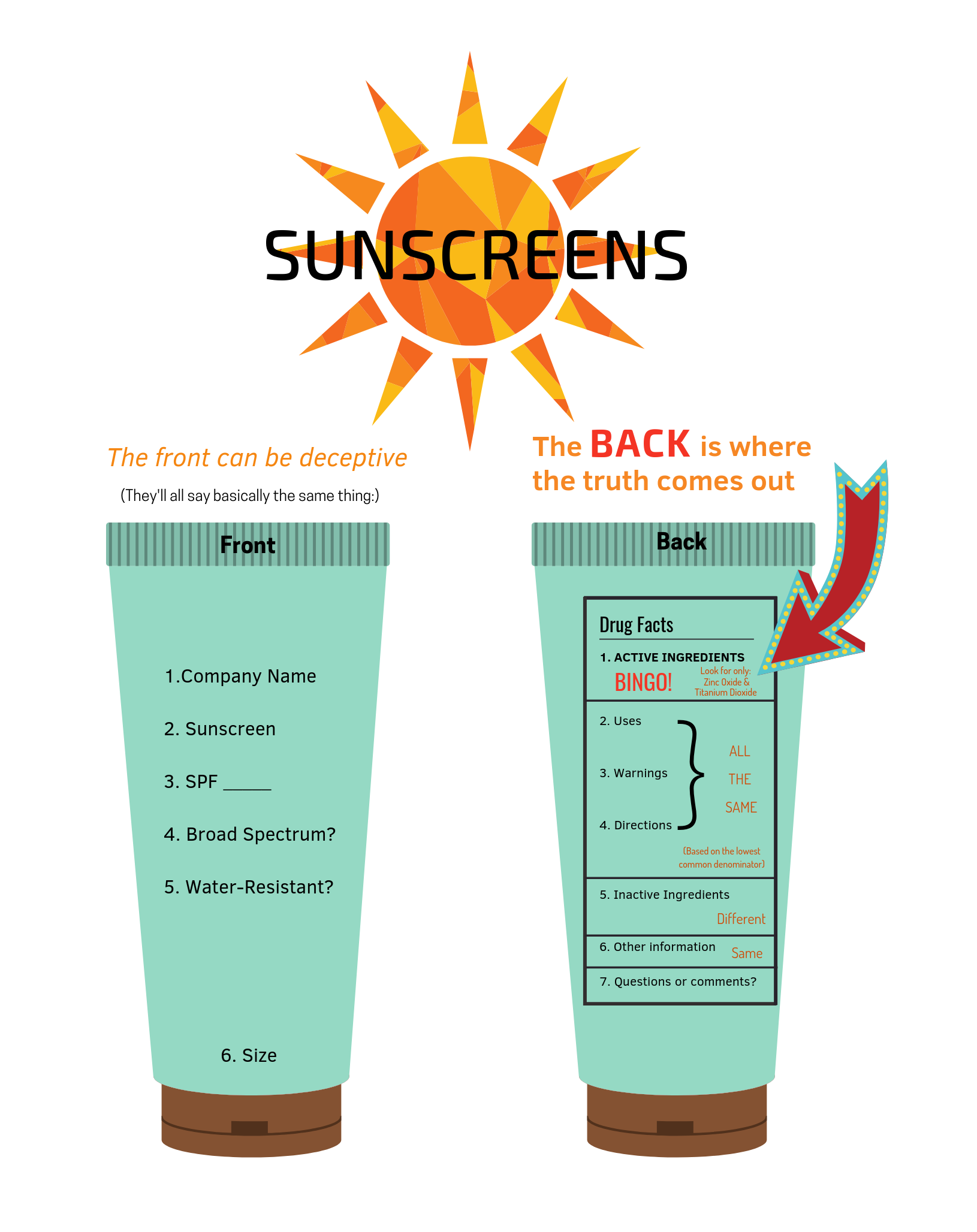

Just as the quality of ingredients determines the effectiveness of a skin lotion, the substrate of a drone’s optical filter determines the clarity of the image. When we ask “what is in sunscreen” for a camera, we are primarily looking at the purity of the optical glass and the nano-treatments applied to it.

Schott Glass vs. Standard Optical Glass

Most professional-grade drone filters, such as those used for 4K and 8K cinematography, utilize B270 or Schott glass. This material is characterized by its high transmission rates and neutral color profile. Unlike standard window glass, which has a green tint due to iron content, this specialized “ingredient” is refined to be perfectly clear. This ensures that the “sunscreen” does not introduce a color cast to the footage, maintaining the integrity of the drone’s high-dynamic-range (HDR) output.

Hydrophobic and Oleophobic Nano-Coatings

A critical component of a drone’s external protection is the “lotus effect” coating. High-altitude flight often involves moving through clouds, mist, or areas with high insect density. Modern drone filters are treated with hydrophobic (water-repelling) and oleophobic (oil-repelling) nano-coatings. These are usually fluorinated polymers that lower the surface tension of the glass. This allows moisture to bead off instantly and prevents fingerprints or grease from blurring the shot. In the world of tech, these are the active ingredients that keep the “skin” of the lens clean in the most demanding flight conditions.

Polarization and Light Modulation: Beyond Simple Protection

For an aerial photographer, sunscreen isn’t just about blocking UV rays; it is about managing the sheer volume of light. This is where Circular Polarizers (CPL) and Neutral Density (ND) filters come into play. These serve as the “darkening agents” in our optical sunscreen.

How Circular Polarizers Act as “Sunglasses”

A CPL filter is composed of a polarizing film sandwiched between two layers of optical glass. This film acts as a microscopic “slat” that only allows light waves vibrating in a specific direction to pass through. When flying over water or glass-heavy urban environments, the CPL removes polarized reflections that would otherwise “blind” the sensor. It deepens the blue of the sky and increases color saturation in foliage—much like how polarized sunglasses provide a clearer, more vivid view of the world on a bright day.

Managing Albedo and Glare in High-Contrast Environments

In snowy environments or over bright white sand, the “albedo” (reflectivity) of the ground can overexpose a drone’s sensor, even at high shutter speeds. The “sunscreen” here involves ND filters, which are made of light-reducing materials like Nitto Denko film or metallic vapor deposition. These ingredients act as “sunglasses” for the drone, reducing the amount of light entering the lens by several “stops” (ND4, ND8, ND16, etc.). This allows the pilot to maintain a cinematic shutter speed (typically double the frame rate) without blowing out the highlights.

Durability and Physical Defense: The Hardware of Protection

The “sunscreen” of a drone camera must also act as a physical barrier. While a liquid sunscreen protects skin through absorption, a drone’s optical shield protects through physical resilience. This requires high-performance structural materials to house the “ingredients” of the lens.

Aerospace-Grade Aluminum Frames

The frame that holds the optical glass is almost always constructed from CNC-machined aerospace-grade aluminum. This material is chosen for its strength-to-weight ratio. Since drones are sensitive to weight changes—which can affect gimbal balance and battery life—the housing of the “sunscreen” must be light enough to not stress the motors, yet strong enough to survive a hard landing or a collision with a stray branch.

Scratch Resistance and Ion-Exchange Tempering

To ensure that the “sunscreen” doesn’t become the source of a blur, many filters undergo an ion-exchange tempering process. By placing the glass in a hot potassium salt bath, smaller sodium ions in the glass are replaced by larger potassium ions. This creates a state of compression on the surface, making the glass significantly harder and more resistant to scratches. This is vital for drones, which often operate in dusty or sandy environments where particles can act like sandpaper against the lens during high-speed flight.

Future Innovations in Sensor Shielding

As drone technology moves toward AI-driven flight and autonomous mapping, the nature of optical “sunscreen” is evolving. We are seeing the integration of smarter materials that do more than just sit on the lens.

Smart Coatings and Electronic Variable Filters

The next generation of drone “sunscreen” involves electronic variable filters. Instead of physical glass layers that must be swapped out, these systems use liquid crystal layers that can change their opacity when an electric current is applied. This “active sunscreen” allows the drone’s AI to adjust the light intake in real-time, responding to changing cloud cover or the transition from sun to shadow during a single flight path.

Remote Sensing and Spectral Filtering

In specialized fields like agriculture and remote sensing, the “sunscreen” is tuned to allow specific wavelengths—such as Near-Infrared (NIR)—while blocking others. These multispectral filters allow drones to “see” the health of crops by measuring the light they reflect. Here, the “ingredients” are precisely calibrated to help the camera identify the “sunburn” (heat stress) on plants, turning the drone into a flying diagnostic tool.

Ultimately, “what is in sunscreen” for a drone is a complex mixture of optical physics, chemical engineering, and mechanical design. From the vacuum-deposited metallic oxides that block UV light to the ion-tempered glass that guards against physical damage, these components are what allow modern drones to capture stunning, professional-grade imagery in the harshest lighting conditions on the planet. For the serious pilot, choosing the right “sunscreen” for their camera is just as important as the drone itself.