Fiber optic drones represent a cutting-edge evolution in unmanned aerial vehicle (UAV) technology, bridging the gap between traditional radio-frequency (RF) controlled drones and tethered systems for mission-critical operations. Unlike conventional quadcopters that rely on wireless signals prone to jamming, interference, or range limitations, fiber optic drones use a physical fiber optic tether to deliver unbreakable connectivity, high-bandwidth data transfer, and even continuous power supply. This makes them ideal for environments where electronic warfare, GPS denial, or long-duration flights are concerns, such as military reconnaissance, infrastructure inspection, and disaster response.

These drones maintain full FPV capabilities, real-time video feeds, and precise control without the spectrum congestion of RF systems. By transmitting data via light pulses through ultra-thin glass or plastic fibers, they achieve latencies under 1 millisecond and bandwidths exceeding 10 Gbps—far surpassing Wi-Fi or LTE alternatives. In this article, we’ll break down their inner workings, from the tether mechanics to flight control and real-world applications.

The Fundamentals of Fiber Optic Tether Technology

At the heart of fiber optic drones is the tether—a lightweight, flexible cable no thicker than a guitar string, often 2-5 mm in diameter, capable of extending 5-20 km depending on the system. This tether serves triple duty: data transmission, power delivery, and physical restraint that prevents the drone from drifting uncontrollably.

How Light Signals Enable Jam-Proof Communication

Fiber optics work on the principle of total internal reflection. Laser diodes at the ground station modulate electrical signals into light pulses (typically at 1310 nm or 1550 nm wavelengths for low attenuation). These pulses travel through the fiber’s core at nearly the speed of light, carrying bidirectional data: commands upward to the drone and telemetry, video, and sensor data downward.

Key advantages of this optical transmission:

- Immunity to EMI/RFI: Unlike RF signals, light in fiber isn’t affected by electromagnetic interference, making it perfect for contested airspace near jammers or power lines.

- High Bandwidth: Supports uncompressed 4K video streams, LiDAR point clouds, and multiple thermal cameras simultaneously.

- Security: Data stays within the physical cable, eliminating hacking risks associated with over-the-air broadcasts.

The drone’s onboard optical transceiver converts these light signals back to electrical ones using photodetectors. Bidirectional communication uses wavelength-division multiplexing (WDM), separating upstream and downstream signals on different colors of light within the same fiber.

Power-Over-Tether (PoT) for Unlimited Endurance

Traditional battery-powered drones like the DJI Mavic 3 last 30-45 minutes, but fiber optic systems draw power directly from the ground. High-voltage DC (up to 10 kV) travels alongside data fibers, stepped down onboard via DC-DC converters to 48V or 12V for motors, avionics, and payloads. This enables indefinite hover times, limited only by tether length and mechanical wear.

Tethers incorporate Kevlar strength members for tensile strength up to 100 kg, ensuring the drone can withstand wind gusts while deploying payloads like 5 kg sensors.

Key Components of a Fiber Optic Drone System

A complete fiber optic drone setup integrates airframe, tether management, and ground control into a seamless ecosystem.

The Drone Airframe and Flight Systems

The airframe is typically a hexacopter or octocopter for redundancy, with brushless motors and carbon-fiber props optimized for tethered ops. Flight controllers like custom variants of Pixhawk process tether-derived commands, fusing them with onboard IMU (inertial measurement units), barometers, and optical flow sensors for stabilization.

Navigation without GPS: In GPS-denied environments, visual odometry and SLAM (Simultaneous Localization and Mapping) algorithms use downward-facing cameras to track position relative to the tether payout. Obstacle avoidance relies on stereo vision or ToF sensors, feeding data back through the fiber for real-time operator overrides.

Payloads include gimbal cameras with 30x optical zoom, hyperspectral imagers for remote sensing, or even robotic arms—all powered indefinitely.

Tether Spool and Deployment Mechanisms

Managing the tether is critical to prevent tangles or excessive drag. Motorized spools with slip rings rotate at up to 100 m/min payout/retrieval speeds. Tension sensors maintain optimal slack (10-20% of deployed length) using feedback loops. Advanced systems employ AI-driven predictive winding, anticipating maneuvers from flight data.

Hybrid tethers blend fiber with copper conductors for power, weighing just 10-20 g/m—light enough for agile flight.

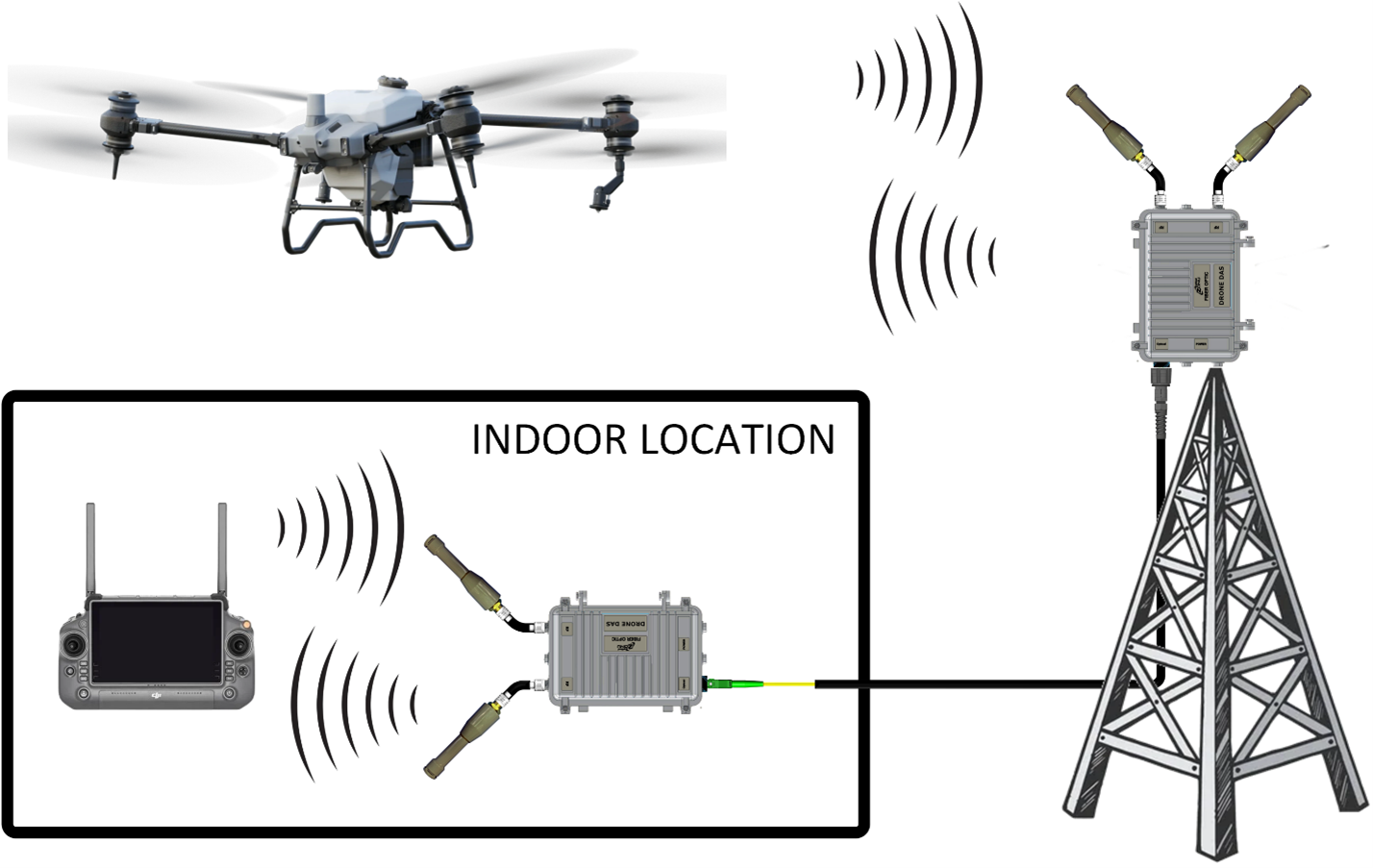

Ground Control Station (GCS)

The GCS is a rugged laptop or console running custom software (often Linux-based with ROS integration). Operators use joysticks for manual control or set waypoints for semi-autonomous paths. The interface displays low-latency FPV feeds, 3D maps from RTK baselines (if available), and health metrics like fiber attenuation or spool tension.

Operational Workflow: From Launch to Mission Execution

Launching a fiber optic drone is straightforward yet precise. The spool starts locked; as the drone ascends, a servo releases fiber incrementally. Commands flow like this:

- Initialization: GCS pings the drone via fiber handshake, calibrating sensors.

- Flight Phase: Pilot inputs translate to PWM signals modulated into light. Drone executes via ESCs (electronic speed controllers).

- Data Loop: Cameras and sensors stream raw data (e.g., 60 fps H.265 video) down-fiber; AI on-ground processes for object detection.

- Emergency Retract: Optical break detection triggers rapid spool-in if fiber snaps.

Latency is sub-5 ms end-to-end, rivaling direct wiring. For autonomy, onboard computers handle stabilization, while ground AI enables swarm coordination across multiple tethered units.

Advantages, Limitations, and Future Innovations

Superior Benefits:

- Range and Endurance: 10+ km reach, 24/7 operation.

- Reliability: 99.99% uptime in EW-heavy zones.

- Data Fidelity: Lossless 8K/360° streaming for aerial filmmaking or mapping.

- Cost-Effectiveness: Reusable tethers reduce per-flight expenses vs. disposable RF drones.

Challenges:

- Mobility Constraints: Tether limits speed (typically <20 m/s) and radius.

- Deployment Logistics: Spools weigh 10-50 kg, requiring vehicles.

- Weather Sensitivity: Ice or abrasion can damage fiber.

Emerging innovations include hybrid RF/fiber failover, airborne repeaters for 50 km+ range, and biodegradable tethers for eco-sensitive areas. Companies like Skydio and Elbit Systems are integrating quantum sensors for beyond-visual-line-of-sight (BVLOS) ops.

Real-World Applications Across Industries

Fiber optic drones excel where RF fails:

- Military ISR: Hovering over battlefields with EO/IR turrets, feeding intel without detection.

- Infrastructure Inspection: Tower climbs, powerline scans with UV cameras for corona discharge.

- Disaster Response: Persistent surveillance post-earthquake, powering thermal imaging for survivor detection.

- Filmmaking and Events: Stable cinematic shots at stadiums, immune to crowd Wi-Fi interference.

- Precision Agriculture: Multispectral mapping over vast fields.

In summary, fiber optic drones redefine tethered flight by leveraging photonics for secure, boundless performance. As autonomous flight tech advances, expect them to dominate high-stakes domains, complementing free-flying UAVs like racing drones in hybrid fleets.