In the rapidly evolving landscape of unmanned aerial vehicle (UAV) design, engineers are increasingly looking toward nature to solve the complex challenges of thermal regulation, structural integrity, and endurance. While the term “microvascular” is traditionally rooted in biology—referring to the intricate network of tiny blood vessels that sustain living tissue—it has emerged as a groundbreaking concept in the field of Tech & Innovation. In drone technology, microvascular systems represent a new frontier of biomimetic engineering, where synthetic networks of micro-channels are integrated into the airframe to perform functions similar to a circulatory system.

As drones become more powerful, carrying sophisticated AI processors and high-capacity batteries, the need for efficient cooling and structural monitoring has never been greater. This article explores the transition of microvascular concepts from the laboratory to the flight line, detailing how this innovation is set to redefine the next generation of autonomous flight.

Understanding the Microvascular Concept: From Biology to Aerostructures

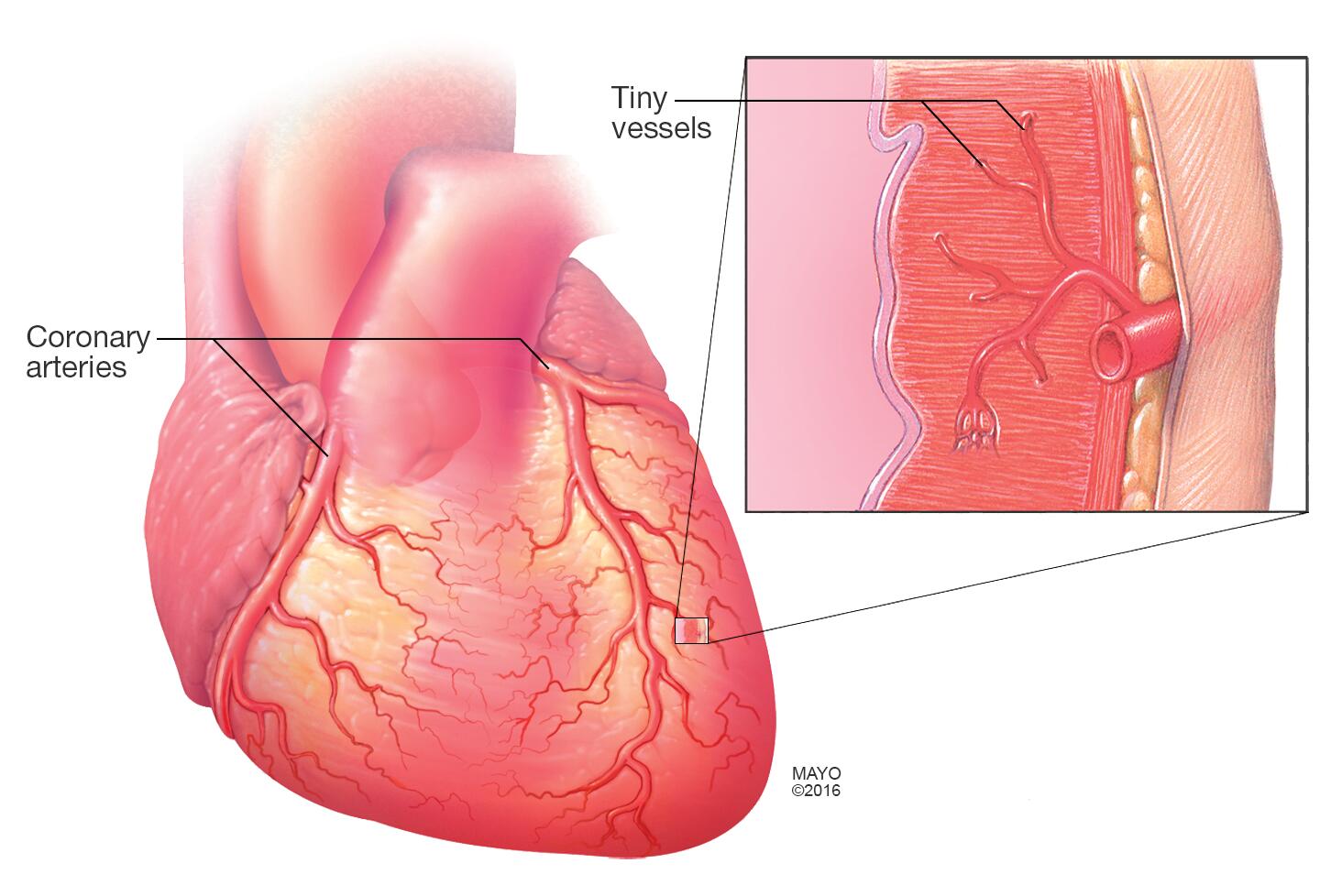

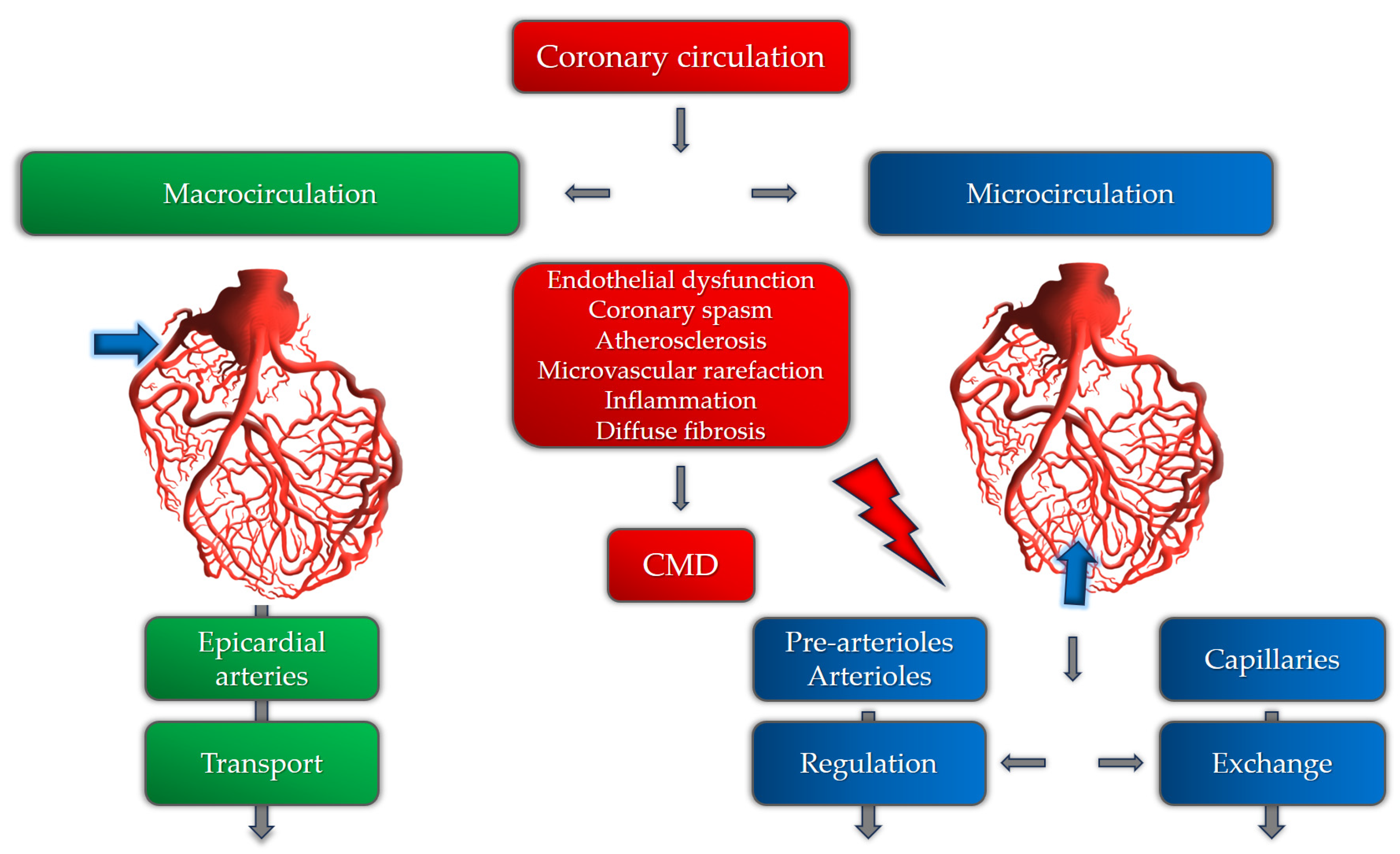

The core of microvascular technology lies in its ability to transport fluids or signals through a vast, decentralized network. In humans, the microvascular system ensures every cell receives oxygen while removing heat and waste. In the world of advanced drone tech, this principle is being applied to create “living” machines that can regulate their own internal environments.

The Biological Blueprint

Nature has spent millions of years perfecting the distribution of resources through microvascular networks. These systems are characterized by their high surface-area-to-volume ratio, which allows for incredibly efficient heat exchange and nutrient delivery. For drone innovators, the goal is to replicate this efficiency. By embedding a synthetic “capillary” network within carbon fiber composites or 3D-printed drone frames, engineers can create a platform that manages stress and heat far more effectively than traditional solid-state materials.

Mimicking Nature for Advanced Engineering

Synthetic microvascular networks are typically composed of channels ranging from 10 to 500 micrometers in diameter. These are not merely tubes; they are integral parts of the drone’s structural skin. Using advanced manufacturing techniques like Vasculatized Composite Manufacturing (VCM), designers can weave these channels into the very fabric of the drone. This allows the aircraft to maintain a light weight—crucial for flight—while gaining the sophisticated internal management capabilities of a biological organism.

Thermal Management and Battery Efficiency

One of the primary hurdles in drone innovation is heat. High-performance flight controllers, 4K transmission systems, and heavy-duty motors generate significant thermal energy. Conventional cooling methods, such as heat sinks and cooling fans, add weight and drag, which directly impacts flight time. Microvascular cooling offers a revolutionary alternative.

Overcoming Heat Constraints in High-Performance UAVs

As we push the boundaries of AI Follow Modes and autonomous mapping, the onboard processors are required to handle massive amounts of data in real-time. This creates “hot spots” that can lead to thermal throttling or hardware failure. A microvascular cooling system circulates a coolant fluid directly through the drone’s chassis, passing through the areas of highest heat concentration. Because the network is distributed throughout the structure, it can dissipate heat across the entire surface area of the drone’s wings and fuselage, effectively turning the airframe into a giant radiator.

Liquid Cooling via Micro-Channels

Unlike the bulky liquid cooling systems found in desktop PCs, drone-based microvascular systems are incredibly thin. These systems utilize the “perspiration” or “circulation” principle. In some advanced designs, the fluid absorbs heat from the electronics and moves it to the leading edges of the propellers or wings, where the rushing air naturally cools the fluid. This creates a closed-loop system that maintains optimal operating temperatures for batteries and sensors, potentially increasing battery efficiency by up to 20% by preventing heat-induced discharge fluctuations.

Structural Health Monitoring and Self-Healing Materials

Beyond cooling, microvascular networks serve a critical role in the safety and longevity of autonomous systems. In the field of remote sensing and long-range mapping, drones are often subjected to extreme environmental stress, leading to microscopic cracks in the airframe that are invisible to the naked eye.

Sensing Damage at the Micro-Scale

Innovation in microvascular tech has led to the development of “sensory” networks. By filling these micro-channels with conductive fluids or pressurized gases, the drone’s onboard AI can monitor changes in pressure or electrical resistance. If a drone’s wing suffers a micro-fracture during a high-G maneuver, the microvascular system detects the “leak” or change in flow immediately. This provides a level of structural health monitoring (SHM) that allows for predictive maintenance, ensuring the drone is grounded before a catastrophic failure occurs during flight.

The Future of Autonomous Repair in Flight

The most “sci-fi” application of microvascular technology is the concept of self-healing airframes. In this scenario, the micro-channels are filled with a two-part epoxy or a specialized healing agent. When a crack forms and ruptures a micro-channel, the healing agent is released into the fracture. Upon contact with the air or a secondary catalyst, the agent hardens, effectively “clotting” the wound and restoring the structural integrity of the drone. For autonomous drones operating in remote areas—such as offshore wind farm inspections or high-altitude atmospheric monitoring—this ability to self-repair could be the difference between a successful mission and a total loss of equipment.

Integrating Microvascular Systems into Drone Design

Implementing a circulatory system into a drone is a feat of extreme engineering. It requires a synergy between material science and fluid dynamics to ensure that the added complexity does not compromise the flight characteristics of the UAV.

Manufacturing Challenges: 3D Printing and Microfluidics

The rise of Additive Manufacturing (3D printing) has been the catalyst for microvascular integration. Traditional manufacturing cannot easily create internal hollow networks within a solid structure. However, with stereolithography (SLA) and selective laser sintering (SLS), engineers can print drone components with pre-designed internal vascularity. The challenge remains in the “plumbing”—ensuring that the micro-pumps required to move the fluid are small enough and consume minimal power so as not to offset the benefits of the system.

Impact on Weight and Aerodynamics

In drone tech, every gram matters. Critics of microvascular systems often point to the weight of the fluid and the pumping mechanism. However, the counter-argument is that by using microvascular cooling, designers can eliminate heavy metal heat sinks and cooling fans. Furthermore, by maintaining the structural integrity of the drone through self-healing and monitoring, the airframe can be built thinner and lighter than a traditional “over-engineered” frame. The result is a highly optimized power-to-weight ratio that favors long-endurance missions.

The Future of Microvascular Tech in Autonomous Systems

As we look toward the future of Tech & Innovation within the drone industry, microvascular systems are positioned to become a standard feature in professional and military-grade UAVs. The transition from simple “flying cameras” to complex “autonomous robots” necessitates a move toward more biological-like internal systems.

Deep-Space and High-Altitude Exploration

The applications extend far beyond terrestrial hobbyist drones. For high-altitude platform stations (HAPS) that stay in the stratosphere for months at a time, or for future drones designed for planetary exploration (like the Mars Ingenuity helicopter’s successors), microvascular systems are essential. They provide the necessary thermal regulation to survive the extreme temperature swings of space and high altitudes while offering the self-healing resilience needed when repair crews are millions of miles away.

Conclusion: A New Frontier for Drone Longevity

What is microvascular technology? In the context of drones, it is the bridge between mechanical engineering and biological efficiency. It is a sophisticated innovation that addresses the three “pain points” of modern UAVs: heat, structural fatigue, and maintenance. By embedding these intricate networks into drone architecture, we are moving toward a new era of “intelligent” hardware—drones that can feel, cool, and heal themselves.

As AI continues to advance the “brain” of the drone, microvascular technology is advancing the “body.” Together, these innovations will allow for longer flights, safer operations, and the ability to operate in the most demanding environments on Earth and beyond. The integration of microvascular networks isn’t just an incremental upgrade; it is a fundamental shift in how we perceive and build the autonomous machines of tomorrow.