In the sophisticated world of unmanned aerial vehicles (UAVs) and advanced flight systems, the hardware often receives the most attention. We marvel at high-torque brushless motors, aerodynamic carbon fiber frames, and high-capacity lithium-polymer batteries. However, beneath the shell of any stable, self-correcting flight platform lies a complex digital dialogue. At the heart of this communication is the I2C bus—the “Inter-Integrated Circuit.”

For flight technology enthusiasts and engineers, understanding the I2C bus is not just a matter of academic interest; it is a fundamental requirement for mastering drone stabilization, navigation, and sensor integration. This protocol acts as the nervous system of the aircraft, carrying vital data from the “senses” (sensors) to the “brain” (flight controller) to ensure that the craft remains level, oriented, and responsive.

The Fundamentals of I2C in Aerial Navigation

To appreciate how a drone maintains a rock-solid hover or follows a precise GPS waypoint, one must first understand the language its components speak. Developed in the early 1980s by Philips Semiconductors, the I2C bus was designed to allow multiple integrated circuits to communicate with one another using a minimal number of physical pins.

What is the I2C Bus Protocol?

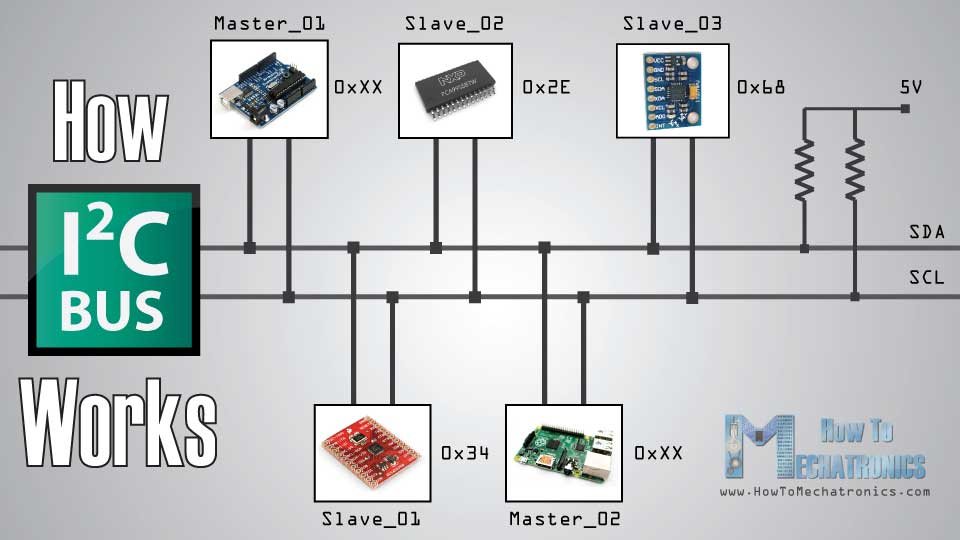

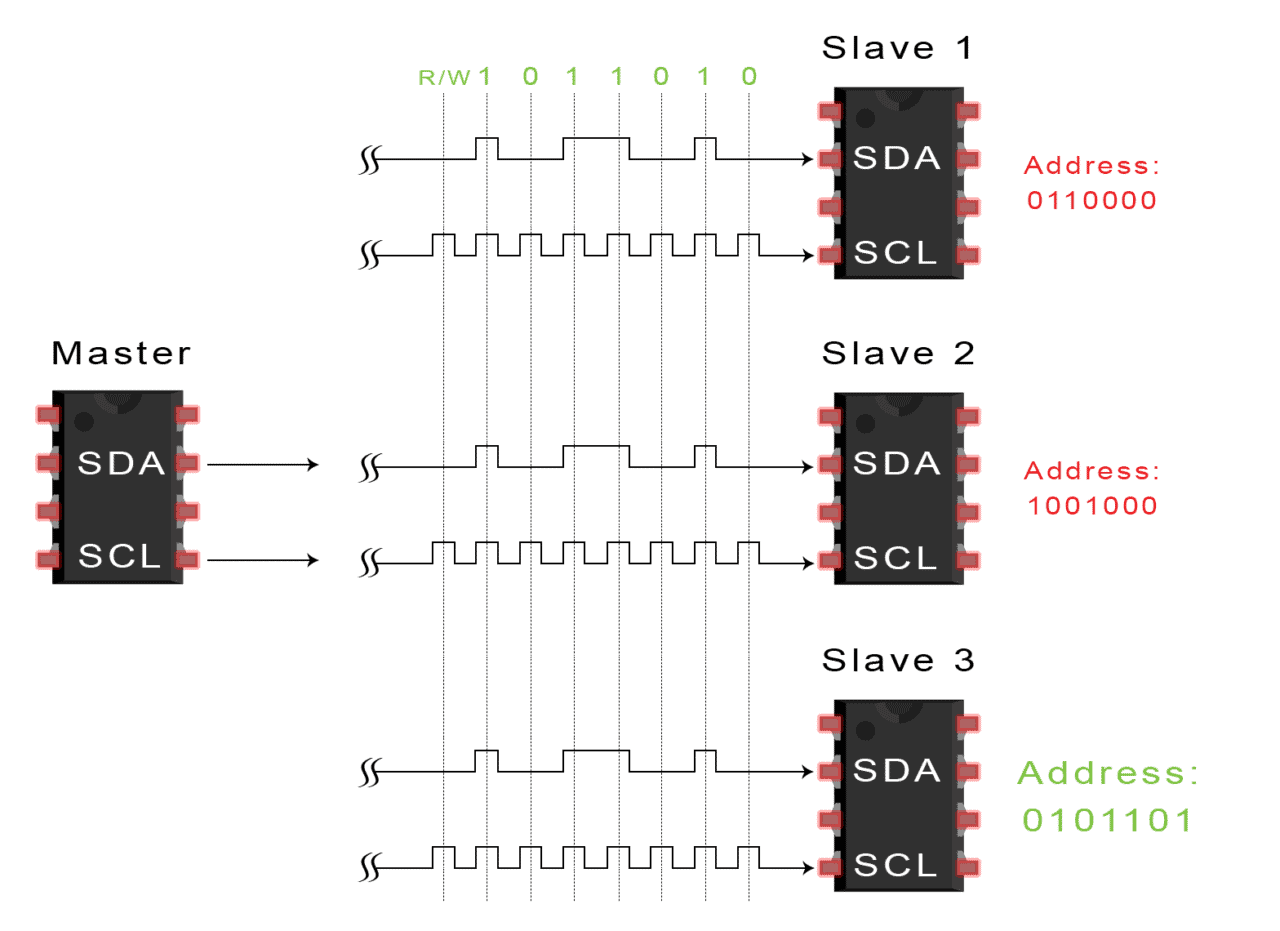

The I2C (Inter-Integrated Circuit) bus is a synchronous, multi-master, multi-slave, packet-switched, single-ended, serial communication bus. In simpler terms, it is a way for different chips on a flight controller or external sensor board to “talk” to each other over a shared set of wires. Unlike UART (Universal Asynchronous Receiver-Transmitter), which typically connects just two devices, I2C allows a single “Master” device to communicate with dozens of “Slave” devices on the same bus. This efficiency is what allows modern flight controllers to be so compact while interfacing with a wide array of peripheral technology.

Master and Slave Architecture in Flight Controllers

In the context of flight technology, the Master device is almost always the MCU (Microcontroller Unit) on the flight controller. The Slaves are the various peripherals, such as the gyroscope, accelerometer, barometer, and digital compass.

The relationship is hierarchical: the flight controller initiates all communication. It requests data from a specific sensor, and that sensor responds. This architecture is vital for flight stability because it prevents data collisions. By controlling the timing of every interaction, the flight controller ensures that it receives the specific data it needs—such as a sudden change in pitch—without being interrupted by less critical data from another sensor.

SDA and SCL: The Two-Wire Communication Standard

One of the primary reasons I2C became the standard for flight technology is its simplicity. It requires only two signal wires:

- SDA (Serial Data Line): The line through which the actual data bits are transferred.

- SCL (Serial Clock Line): The line that carries the clock signal, which synchronizes the timing of the data transfer between the master and slave.

By using a clock signal, I2C eliminates the need for both devices to agree on a set baud rate (as is necessary in UART). This makes the communication more robust against timing errors, which is critical when a drone is experiencing the high-vibration environment of spinning propellers.

Why I2C is Essential for Drone Stabilization Systems

Stabilization is the most computationally intensive aspect of flight technology. A drone must calculate its position and make adjustments to motor speeds hundreds or even thousands of times per second. The I2C bus is the conduit for the data that makes these calculations possible.

Integrating Inertial Measurement Units (IMUs)

The IMU is the most critical sensor in any flight stabilization system. It typically consists of a 3-axis gyroscope and a 3-axis accelerometer. These sensors detect the slightest rotational movements and linear acceleration.

Through the I2C bus, the flight controller constantly polls the IMU for updates. When a gust of wind tips the drone three degrees to the left, the IMU detects the change, sends the data via the SDA line to the flight controller, and the PID (Proportional-Integral-Derivative) loop adjusts the motors to counter the movement. Without the low-latency, reliable communication provided by the I2C protocol, the drone would be unable to react fast enough to maintain flight, resulting in an immediate crash.

Managing Barometers and Digital Compasses

While the IMU handles rapid movements, the barometer and magnetometer (digital compass) handle environmental orientation. The barometer measures atmospheric pressure to determine altitude, while the magnetometer senses the Earth’s magnetic field to determine heading.

Because I2C is a bus-based system, these sensors can live on the same two wires as the IMU. The flight controller uses unique “hexadecimal addresses” to talk to each one. For example, it might ask the IMU for orientation data, then immediately ask the barometer for altitude data, all over the same SDA and SCL lines. This allows for complex “Altitude Hold” and “Position Hold” features that are staples of modern GPS drones.

Real-Time Data Throughput and Low Latency Requirements

In flight technology, latency is the enemy. If there is a delay in sensor data reaching the processor, the stabilization corrections will be “out of phase,” leading to oscillations or “toilet bowl” effects. I2C supports different speeds, typically 100 kbps (Standard Mode) and 400 kbps (Fast Mode). Most modern flight systems utilize Fast Mode or even “Fast Mode Plus” (1 Mbps) to ensure that the data throughput is sufficient to feed high-frequency PID loops, ensuring a buttery-smooth flight experience for the pilot.

Implementing I2C in GPS and External Sensor Modules

As drones have evolved from simple toys to advanced mapping and sensing platforms, the need for external sensors has grown. This is where the flexibility of the I2C bus truly shines.

Multi-Device Support and Bus Addressing

One of the most powerful features of I2C is its ability to support multiple devices on a single bus. Each I2C-compatible sensor has a hard-coded or configurable 7-bit address. When the flight controller sends a command, it includes this address. Only the sensor with the matching address responds.

This is particularly useful in “Flight Technology” setups where a pilot might want to add an external LiDAR sensor for obstacle avoidance or an optical flow sensor for indoor positioning. Instead of needing entirely new ports on the flight controller, these sensors can often be “daisy-chained” or added to the existing I2C bus.

Connecting External Magnetometers for Directional Accuracy

Internal magnetometers on flight controllers are often prone to electromagnetic interference (EMI) from the high-current wires powering the motors. To solve this, flight technology engineers often mount the compass inside the GPS puck, which is raised on a mast away from the electronics.

This external compass almost always communicates via I2C. By running the SDA and SCL wires alongside the GPS’s UART wires, the flight controller can receive highly accurate directional data far from the noise of the power distribution board. This is the secret behind the precise “Return to Home” (RTH) accuracy seen in professional-grade UAVs.

Overcoming Distance Limitations in Drone Wiring

While I2C is incredibly efficient, it was originally designed for communication between chips on the same circuit board. In flight technology, we often push the limits by running I2C wires to the ends of drone arms or up to GPS masts.

Because I2C uses “open-drain” signals, it is sensitive to capacitance in the wires. As the wires get longer, the signal can become “rounded,” leading to data errors. Engineers combat this by using specific pull-up resistors or I2C bus extenders. Understanding these physical constraints is vital for anyone designing long-range or large-scale autonomous flight systems.

Troubleshooting and Optimizing I2C for Reliable Flight

Even the most advanced flight technology can be brought down by a single “I2C Error.” If you have ever looked at a flight controller’s status bar and seen an “I2C Error Count” climbing, you know how stressful this can be.

Pull-up Resistors and Signal Integrity

For the I2C bus to function, the SDA and SCL lines must be pulled “High” (usually to 3.3V) by resistors. Most flight controllers have these built-in, but when adding multiple external sensors, the total resistance on the bus changes. If the resistance is too high, the signal cannot rise fast enough for high-speed communication. If it is too low, it draws too much current. Professional flight tech integration requires a careful balance of these resistors to maintain a clean square-wave signal.

Resolving Address Conflicts in Complex Flight Systems

A common issue in advanced drone builds is an “address conflict.” This happens when two different sensors—for example, a barometer and an OLED telemetry screen—share the same I2C address. When the flight controller sends a command, both devices try to speak at once, resulting in garbled data and a system hang. Solving this requires deep-diving into sensor datasheets to change the hardware address or using an I2C multiplexer to switch between different branches of the bus.

Future Alternatives: Is I2C Still the King of Flight Tech?

As flight technology moves toward even higher data rates—such as those required for high-definition 3D mapping and real-time AI obstacle avoidance—some are looking toward SPI (Serial Peripheral Interface) or CAN Bus (Controller Area Network) as alternatives. SPI is faster, and CAN Bus is much more robust over long distances and electrically noisy environments.

However, the I2C bus remains the industry standard for the vast majority of drone sensors due to its low pin count and the massive ecosystem of compatible chips. Its role in flight technology is secure for the foreseeable future, continuing to serve as the invisible bridge between a drone’s physical reality and its digital intelligence.

In conclusion, the I2C bus is much more than a simple pair of wires; it is the fundamental protocol that enables the complex choreography of modern flight. By facilitating seamless communication between the flight controller and an array of sensors, I2C ensures that our drones remain stable, our navigation remains accurate, and our flight technology continues to push the boundaries of what is possible in the sky.