Drones, also known as quadcopters, UAVs, or unmanned aerial vehicles, have revolutionized industries from aerial filmmaking to agriculture and search-and-rescue operations. But how exactly are these marvels of modern engineering brought to life? The process of making a drone is a blend of cutting-edge design, precision manufacturing, and rigorous testing, often involving teams of engineers, robotic assembly lines, and advanced software integration. Whether it’s a compact micro drone for indoor racing or a professional-grade FPV rig for high-speed pursuits, the manufacturing journey follows a structured path. In this article, we’ll break down the key stages, from initial concept to flight-ready product, drawing on insights from leading manufacturers like DJI and custom builders in the racing drones scene.

Design and Prototyping: The Blueprint Stage

The creation of any drone begins with meticulous design and prototyping. Engineers start by defining the drone’s purpose—whether it’s for cinematic aerial filmmaking, surveying with mapping capabilities, or agile FPV racing. Using computer-aided design (CAD) software like SolidWorks or Fusion 360, they model the frame, propulsion system, and payload integration.

Key considerations include aerodynamics, weight distribution, and modularity for accessories like gimbal cameras. For instance, consumer models like the DJI Mini 4 Pro prioritize lightweight construction under 250 grams to comply with regulations, while industrial UAVs incorporate rugged materials for durability.

Prototyping often employs 3D printing with materials like nylon or carbon fiber composites. Rapid iterations test factors such as center of gravity and vibration dampening. Wind tunnel simulations and computational fluid dynamics (CFD) refine airflow over propellers and arms. Once a prototype flies successfully—often via early Betaflight firmware tuning—it’s ready for production scaling. This phase can take months, ensuring the drone excels in navigation and stabilization systems.

Material Selection in Design

Materials are chosen for strength-to-weight ratios. Carbon fiber frames dominate high-end racing drones for rigidity, while injection-molded plastics suit budget quadcopters. Aluminum alloys add robustness for enterprise models with thermal imaging payloads.

Frame Manufacturing: Building the Skeleton

With designs finalized, production shifts to fabricating the drone’s frame, the structural backbone. Mass production uses CNC machining for precision cutting of carbon fiber sheets or aluminum extrusions. Robotic arms slice and shape components, ensuring tolerances as tight as 0.1mm.

For smaller micro drones, injection molding creates plastic frames in high volumes, often in factories in Shenzhen, China, the global hub for drone assembly. Carbon fiber frames, popular in FPV setups, undergo layup processes where pre-impregnated fibers are layered, cured in autoclaves under heat and pressure, then trimmed by water jets.

Surface treatments like anodizing prevent corrosion, while custom paint jobs or decals are applied via UV printing for branding. Quality checks via laser scanning verify dimensions before frames move to assembly lines. This stage emphasizes scalability—DJI plants produce thousands daily, integrating automation for consistency.

Propulsion and Power Systems: The Heart of Flight

No drone flies without powerful propulsion. Motors—typically brushless DC types like T-Motor or EMAX—are assembled next. These feature neodymium magnets and copper windings, wound by automated machines and balanced on spin testers to minimize vibrations.

Propellers, often polycarbonate or carbon fiber, are molded in multi-cavity dies. Sizes range from 5-inch for racing drones to 20-inch for heavy-lift models. Electronic speed controllers (ESCs) regulate motor power, soldered onto power distribution boards.

Power comes from LiPo batteries, with cells stacked and encased in fire-retardant polymers. Battery management systems (BMS) prevent overcharging. Integration involves mounting motors to frame arms, securing props with nylon nuts, and wiring ESCs in an X or H configuration for quadcopters.

Electronics Integration: Brains and Sensors

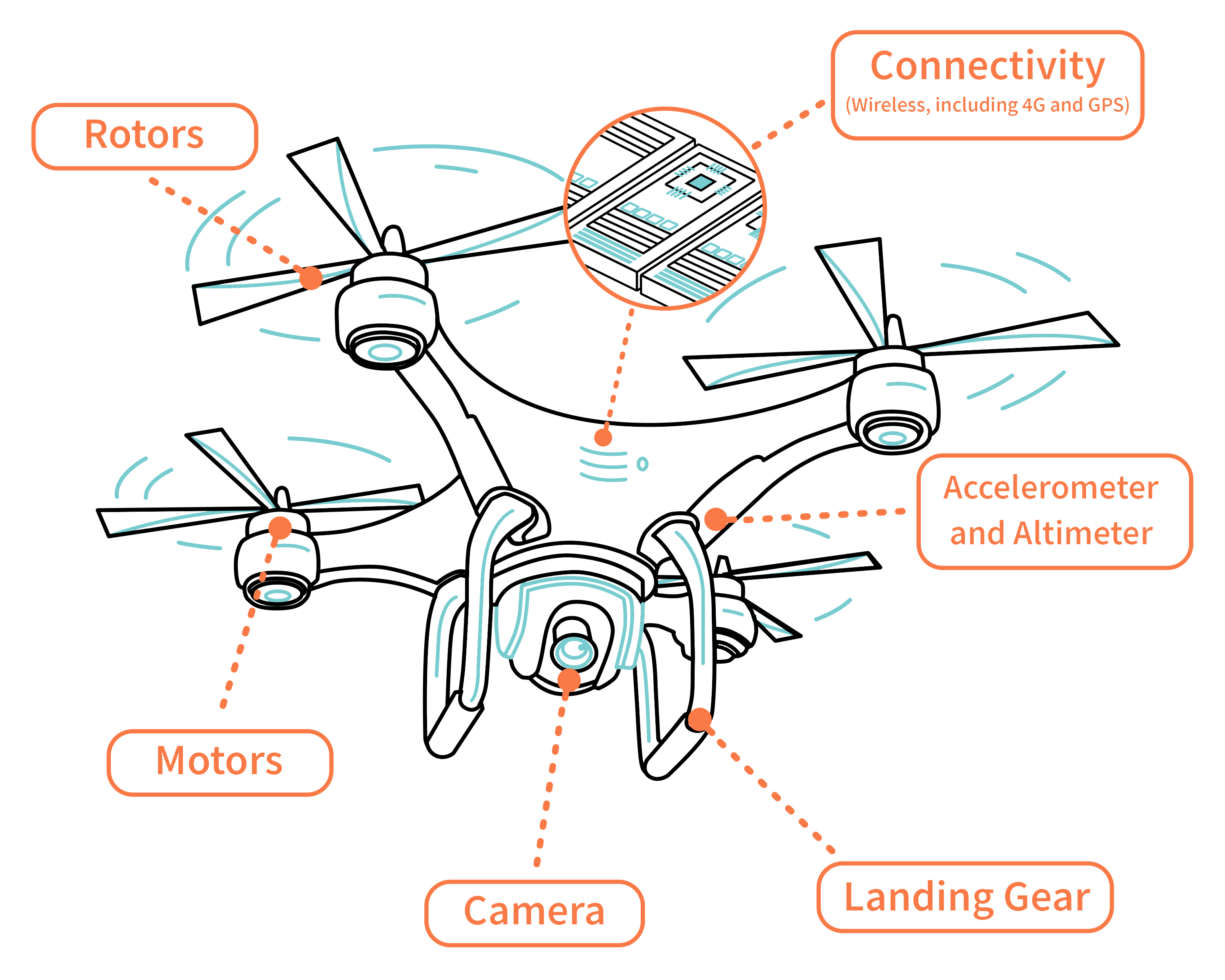

The electronics stack transforms the frame into a smart flyer. At the core is the flight controller, such as Pixhawk for pro builds or STM32-based boards for consumer drones. These run firmware like ArduPilot or iNav, processing data from an array of sensors.

Key Sensors and Flight Tech

- IMU (Inertial Measurement Unit): Combines accelerometers and gyroscopes like the MPU6050 for stabilization systems.

- GPS Modules: u-blox receivers enable precise navigation and return-to-home functions.

- Barometers and Magnetometers: For altitude and heading hold.

- Advanced options include LiDAR for obstacle avoidance or optical flow sensors for indoor flight.

Cameras are wired in: 4K gimbal cameras with optical zoom, GoPro Hero action cams, or thermal imagers for remote sensing. Video transmitters handle FPV systems.

Wiring harnesses, often custom PCB stacks, connect everything. Soldering robots ensure clean joints, while conformal coatings protect against moisture. Firmware flashing via USB or JTAG tunes PIDs for smooth autonomous flight and AI follow mode.

Final Assembly, Testing, and Packaging

Assembly lines buzz with human-robot collaboration. Frames receive electronics, motors, and payloads. Controllers are paired via binding processes for radio protocols like FrSky or Crossfire.

Testing is exhaustive:

- Bench Tests: Power-up checks for ESC calibration, sensor calibration, and motor spin-up without props.

- Hover Tests: Suspended flight verifies stability.

- Flight Tests: In controlled arenas, drones perform maneuvers, GPS acquisition, and failsafe modes.

- Payload Tests: For models with cameras, test cinematic shots or obstacle avoidance.

Stress tests simulate crashes, while burn-in runs age components. Pass rates exceed 99% for brands like DJI. Approved units get firmware updates, serial numbering, and packaging with batteries, propellers, cases, manuals, and apps.

Custom drones for racing drones or DIY builds skip mass production, using kits from iFlight or GEPRC. Enthusiasts assemble at home, tuning via Betaflight configurators.

Innovations Shaping Drone Manufacturing

Future factories will leverage AI for predictive maintenance and 3D-printed electronics. Sustainable materials like bio-composites reduce environmental impact. As tech & innovation advances, drones will integrate swarm capabilities and edge computing for real-time remote sensing.

In summary, making drones is a symphony of precision engineering and innovation, resulting in machines that capture stunning aerial filmmaking footage or map vast terrains. From frame to flight, every step ensures reliability and performance, powering the drone revolution.