The question of “what should be the temperature of cooked turkey” might seem straightforward, but delving into the nuances of achieving perfectly cooked poultry reveals a fascinating intersection of culinary science and technological precision. While the ultimate goal is a safe and delicious meal, the methods we employ to ensure that outcome have been significantly enhanced by advancements in technology, particularly within the realm of sensor technology and data analysis. This exploration will focus on how precise temperature measurement, a core tenet of many technological fields, plays a pivotal role in achieving optimal results when cooking turkey, and how this principle is mirrored in various tech applications.

The Science of Safely Cooked Poultry: Temperature as a Critical Indicator

Achieving the correct internal temperature for turkey is paramount for both food safety and culinary quality. Undercooked poultry can harbor harmful bacteria, while overcooked turkey can become dry and unappetizing. The established safe internal temperature is a result of extensive research into microbial inactivation and the physical changes that occur within meat as it cooks. This pursuit of a precise, quantifiable metric underscores a fundamental principle shared across many technological disciplines: the importance of accurate measurement for controlled outcomes.

Microbial Inactivation and the Role of Heat

The primary driver behind establishing a minimum safe internal temperature for turkey is the need to eliminate pathogenic microorganisms such as Salmonella and Campylobacter. These bacteria, commonly found in raw poultry, can cause severe foodborne illnesses. Scientific studies have demonstrated that holding poultry at specific temperatures for certain durations effectively inactivates these pathogens. The U.S. Department of Agriculture (USDA) recommends an internal temperature of 165°F (74°C) in the thickest part of the breast and thigh, and also in the wing joint. This temperature is considered sufficient to kill harmful bacteria.

The Thermal Death Curve: A Technological Perspective

The concept of the “thermal death curve” is a scientific principle that directly informs food safety guidelines. It illustrates the relationship between temperature and the time required to kill a specific number of microorganisms. Higher temperatures lead to a more rapid reduction in microbial populations. This principle is akin to the performance characteristics of electronic components under varying thermal loads or the operational parameters of sensors that must function reliably within specific temperature ranges. Understanding these curves allows for the establishment of precise temperature and time thresholds, ensuring safety without compromising quality.

Protein Denaturation and Juiciness

Beyond safety, temperature profoundly impacts the texture and juiciness of the cooked turkey. As turkey cooks, the proteins within the muscle fibers undergo denaturation. This process causes the proteins to unwind and coagulate, leading to the familiar changes in texture. When turkey reaches the ideal temperature, the muscle fibers have contracted sufficiently to expel a significant amount of moisture, but not so much that the meat becomes dry and stringy. The goal is to reach a temperature that balances protein coagulation with moisture retention.

Heat Transfer Dynamics: Conduction, Convection, and Radiation

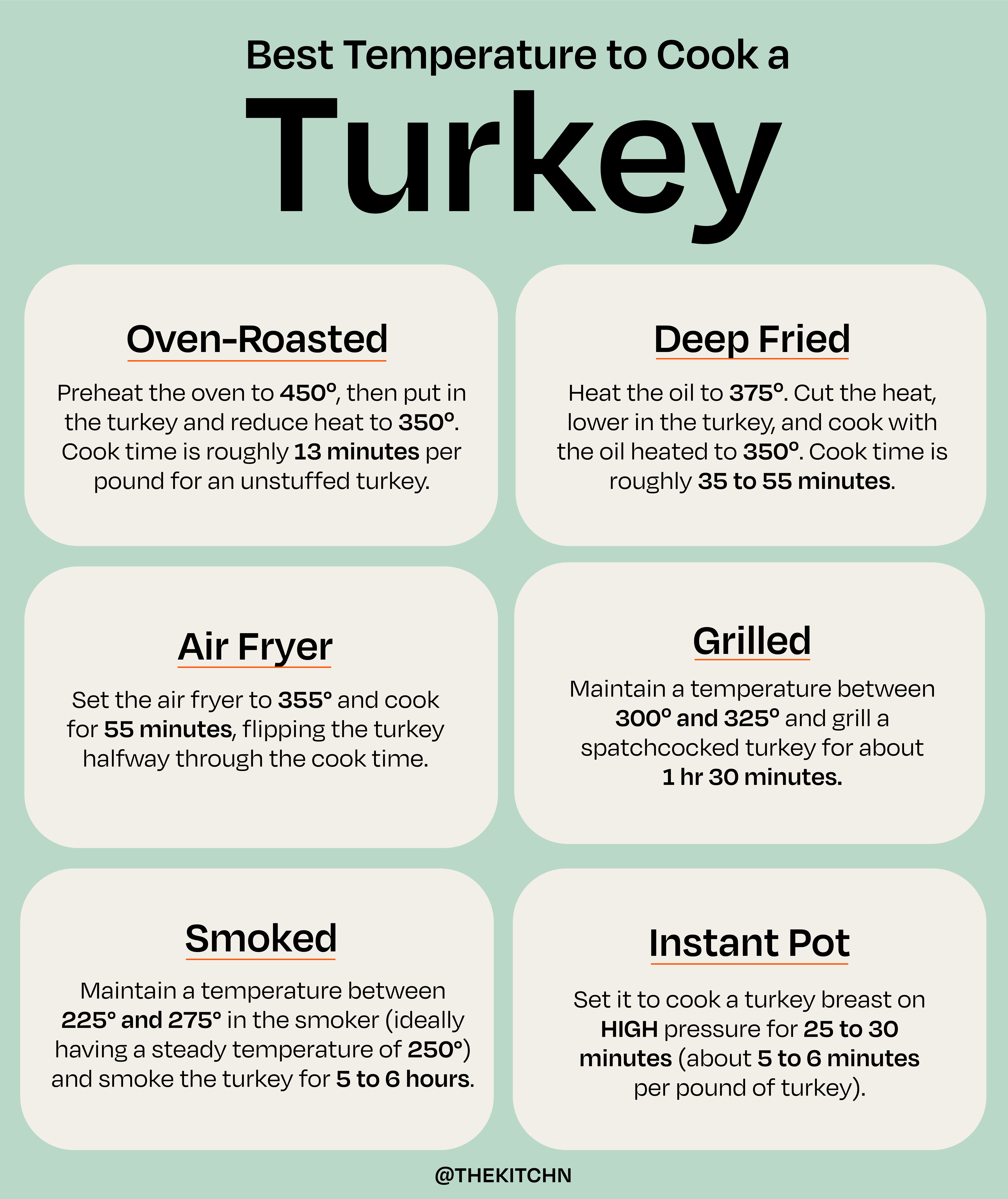

The way heat is transferred to and through the turkey is a critical factor in achieving uniform cooking. Whether roasting in an oven, smoking, or brining and then roasting, understanding the principles of heat transfer is essential. Conduction occurs when heat is transferred through direct contact, such as from the roasting pan to the turkey. Convection involves the movement of heated air or liquid around the turkey, carrying heat with it. Radiation, such as from the heating elements of an oven, also contributes to the cooking process. Mastering these dynamics, often through controlled environments and precise temperature regulation, is key to consistent results. This mirrors the challenges and solutions found in engineering disciplines where efficient and controlled heat transfer is crucial for system performance and longevity.

Precision Measurement: The Technological Backbone of Perfect Turkey

The pursuit of the perfect internal temperature for turkey relies heavily on accurate and reliable temperature measurement. This is where the principles of sensor technology and calibration, vital to numerous technological fields, become directly applicable to the culinary arts. Inaccurate thermometers can lead to undercooked, unsafe food or overcooked, dry meat. The development and refinement of thermometers have been driven by the same need for precision that fuels innovation in aerospace, medical devices, and industrial automation.

Thermometer Technologies: From Mercury to Digital

Historically, mercury thermometers were common for cooking. However, these have largely been replaced by more accurate and user-friendly digital thermometers. Digital thermometers utilize thermistors or thermocouples to measure temperature. These electronic sensors convert thermal energy into an electrical signal, which is then processed by a microchip and displayed as a numerical reading. The accuracy of these devices is a testament to advancements in material science and microelectronics.

Calibration and Accuracy Standards: Ensuring Reliability

Just as critical components in technological systems require rigorous calibration to ensure they operate within specified tolerances, thermometers used for cooking should also be accurate. Calibration involves comparing the thermometer’s reading to a known standard, such as ice water (32°F/0°C) or boiling water (212°F/100°C at sea level). Many high-quality digital thermometers are factory-calibrated, but users can and should periodically check their accuracy. This emphasis on calibration and accuracy is a direct parallel to the stringent quality control measures employed in manufacturing electronics, medical equipment, and scientific instruments.

Advanced Thermometry for Culinary Professionals

For those seeking the highest level of precision, advanced thermometer technologies offer even greater accuracy and features. Infrared thermometers, for example, can measure surface temperature without contact, providing quick readings. However, for ensuring the internal temperature of a turkey, probe thermometers are indispensable. Many modern digital probe thermometers offer features like programmable alarms that alert the user when the desired temperature is reached, or multiple probes to monitor different parts of the turkey simultaneously. This level of sophistication in a culinary tool reflects the integration of advanced sensing and control systems seen in fields like industrial process monitoring and environmental sensing.

Integrating Technology for Optimal Turkey Cooking

The principles of precise temperature measurement and controlled heat application extend beyond simple thermometer usage. Modern cooking techniques and appliances are increasingly incorporating technology to achieve consistently excellent results, mirroring the trend towards smart and automated systems in other industries.

Smart Ovens and Programmable Cooking

The advent of smart ovens represents a significant technological leap in home cooking. These ovens often feature built-in temperature probes that communicate directly with the oven’s control system. Users can select a desired internal temperature for their turkey, and the oven will automatically adjust the cooking time and temperature to achieve that target, ensuring both safety and optimal doneness. This is analogous to sophisticated automated control systems used in manufacturing plants, where sensors provide real-time data to adjust machinery for optimal output and quality.

Data Logging and Analysis in Culinary Applications

While not as prevalent as in industrial settings, the concept of data logging and analysis is beginning to emerge in high-end culinary applications. Some advanced cooking devices allow users to track cooking parameters over time, providing insights into how different variables affect the final outcome. This data can be used to refine recipes and techniques, much like engineers analyze performance data from prototypes or operational systems to identify areas for improvement. This systematic approach to understanding and optimizing a process through data is a core tenet of modern technological development.

The Future of Culinary Temperature Control

As technology continues to advance, we can expect even more integrated and intelligent solutions for cooking. Imagine sensors that can not only measure temperature but also assess moisture content or the degree of protein denaturation, providing a more holistic picture of the turkey’s readiness. This would represent a further blurring of the lines between traditional culinary practices and cutting-edge technological innovation, where precise, multi-faceted sensing and control become the norm for achieving perfect results. The pursuit of optimal outcomes through sophisticated measurement and feedback loops is a universal goal, whether it’s ensuring the structural integrity of a drone or the perfect doneness of a holiday roast.