The phrase “cupped propellers” in the drone world isn’t about a literal depression or hollow in the material. Instead, it refers to a specific wear pattern that can emerge on the edges of drone propellers. This phenomenon is a visual indicator of forces at play during flight, primarily related to airflow and potential stress. Understanding what causes cupping, its implications, and how to address it is crucial for any drone pilot aiming for optimal performance, efficiency, and safety. While it might sound like a minor cosmetic issue, ignoring cupped propellers can lead to a cascade of problems that affect your drone’s flight characteristics and, in severe cases, its airworthiness.

The Aerodynamic Origins of Propeller Cupping

At its core, propeller cupping is an aerodynamic issue, manifesting as a subtle change in the propeller’s edge profile. It’s not a manufacturing defect but rather a result of how the propeller interacts with the air during thousands of rotations per minute. The forces involved are complex, but understanding the basic principles of lift and airflow can shed light on this phenomenon.

Understanding Propeller Lift and Airflow Dynamics

Drone propellers, much like aircraft wings, generate lift by manipulating airflow. As a propeller blade rotates, it creates an area of lower pressure above its surface and an area of higher pressure below. This pressure difference is what propels the drone upwards. The shape of the propeller blade, including its airfoil cross-section and pitch, is meticulously designed to optimize this lift generation.

However, this constant interaction with air, especially under varying flight conditions, can induce stress on the propeller’s leading and trailing edges. The leading edge is the part of the propeller that first encounters the air, and the trailing edge is where the air separates. The airflow dynamics at these points are particularly intense. Factors like airspeed, angle of attack (the angle between the propeller blade and the oncoming air), and the rotational speed all contribute to the forces exerted on the propeller material.

Leading Edge Erosion and Its Impact

When we talk about cupping, we are often referring to a form of leading-edge erosion or deformation. Imagine the propeller slicing through the air. Tiny particles of dust, debris, or even water droplets in the air can strike the leading edge at high velocity. Over time, these repeated impacts can cause microscopic damage, leading to a gradual wearing away or a subtle reshaping of the material. This is analogous to how sandblasting can shape materials, albeit on a much smaller and more gradual scale.

Furthermore, the constant flexing and vibration inherent in high-speed propeller rotation can also contribute to material fatigue and subtle deformation. While propellers are designed to withstand these stresses, cumulative effects over many flight hours can lead to visible changes. The “cupping” itself is often a result of the material being pushed or worn away in a way that creates a slight concavity or groove along the leading edge. This isn’t a sharp edge anymore but a more rounded or “cupped” profile.

Identifying and Diagnosing Cupped Propellers

Recognizing cupped propellers is the first step towards addressing the issue. It requires a keen eye and a systematic approach to propeller inspection. While the term “cupped” might evoke a strong visual image, the actual manifestation can be subtle.

Visual Inspection Techniques

The most straightforward method is a thorough visual inspection of each propeller. This should be done before every flight, especially if you’ve recently encountered challenging flight conditions or have accumulated significant flight hours.

- Look for edge deformation: Pay close attention to the leading edge of each propeller blade. Instead of a sharp, crisp edge, you might notice a slightly rounded or grooved appearance. This is the “cupping.”

- Check for nicks and chips: While cupping is a more uniform deformation, look for any nicks, chips, or gouges along the edges. These are signs of physical impact and can exacerbate the cupping effect.

- Examine for uneven wear: Compare the wear pattern across different blades of the same propeller, and also between propellers of a set. Significant differences can indicate an imbalance or a problem with a specific motor or propeller.

- Inspect for cracks: In more severe cases, you might observe hairline cracks, especially near the root or tip of the blade. Any sign of cracking is an immediate indicator that the propeller is compromised and needs replacement.

The Importance of Propeller Balancing

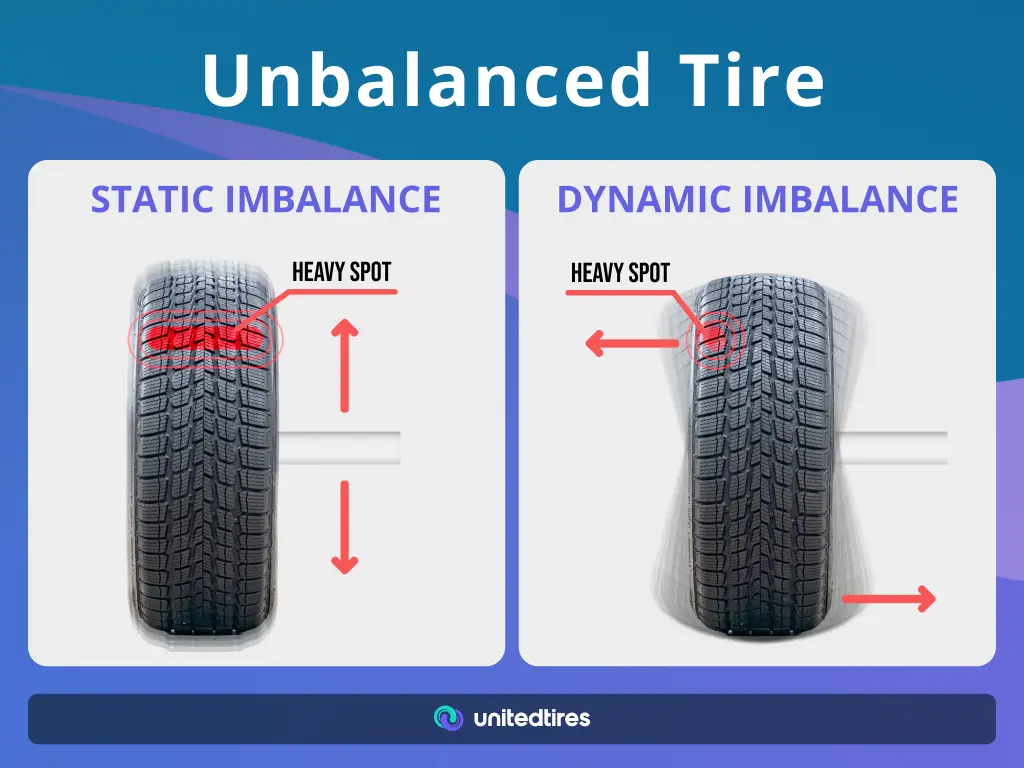

Propeller balance is intrinsically linked to wear and tear. An unbalanced propeller will vibrate excessively during flight. This vibration is not only detrimental to flight stability and sensor readings but also accelerates wear on both the propellers and the drone’s motors. If a propeller is cupped unevenly, it can become unbalanced, creating a vicious cycle.

- Vibration as a symptom: If you notice increased vibrations during flight, or if your flight controller logs indicate unusual vibration levels, it’s a strong sign that your propellers might be compromised, potentially through cupping.

- Impact on motors: Excessive vibration can put undue stress on the motor bearings and windings, leading to premature motor failure. This is a more costly repair than replacing propellers.

- Compromised flight data: For drones used in professional applications like mapping or surveying, unbalanced propellers can lead to inaccurate data due to shaky footage or imprecise positioning.

Implications of Cupped Propellers on Drone Performance

The subtle changes in propeller shape due to cupping can have significant and far-reaching implications for your drone’s flight performance, efficiency, and safety. It’s not just about aesthetics; it’s about the fundamental aerodynamics that keep your drone airborne.

Reduced Flight Efficiency and Increased Power Consumption

A cupped propeller is no longer operating with its optimal aerodynamic profile. The deformation, especially along the leading edge, disrupts the smooth flow of air over the blade. This disruption leads to increased drag and a reduction in lift.

- Lower lift generation: The propeller has to work harder to generate the same amount of lift. This means the motors need to spin faster or at a higher power setting to maintain altitude or achieve desired flight maneuvers.

- Increased energy consumption: Consequently, this increased effort translates directly into higher power consumption from the drone’s battery. You’ll notice a shorter flight time and reduced overall endurance. For professional operations that rely on extended flight times, this can be a major productivity killer.

- Heat generation: The increased strain on the motors and the less efficient airflow can also lead to higher operating temperatures, potentially affecting the lifespan of motor components.

Compromised Flight Stability and Control

The primary role of propellers is to provide stable and controlled thrust. When their aerodynamic integrity is compromised, so is the drone’s ability to fly predictably.

- Unpredictable thrust: The reduced and potentially uneven thrust generated by cupped propellers can make the drone less responsive to control inputs. Gentle maneuvers might become jerky, and maintaining a steady hover can become challenging.

- Increased susceptibility to wind: A drone with compromised propellers will be more susceptible to wind gusts and turbulence. It will struggle to maintain its position and orientation, making precise flight in adverse weather conditions extremely difficult, if not impossible.

- Potential for flyaway or crashes: In severe cases, the loss of thrust and stability can lead to a loss of control, potentially resulting in a flyaway or a crash. This is the most critical safety concern associated with ignoring propeller wear.

Preventive Measures and Best Practices

The good news is that propeller cupping, and the issues it causes, can be largely mitigated through diligent maintenance and adherence to best practices. Proactive care of your drone’s propellers is an investment in its longevity and your flying experience.

Regular Inspection and Replacement Schedule

The cornerstone of propeller maintenance is a consistent inspection routine.

- Pre-flight checks: As mentioned, a quick visual inspection before every flight is paramount. Look for any signs of damage or unusual wear.

- Post-flight assessment: After flights, especially in dusty or challenging environments, it’s a good practice to inspect your propellers more thoroughly.

- Manufacturer recommendations: Adhere to the manufacturer’s recommended replacement intervals for propellers. These are often based on flight hours or a specific number of cycles. Don’t push your propellers beyond their intended lifespan.

- Consider flight conditions: If you frequently fly in harsh conditions (e.g., sandy deserts, near saltwater, or in dusty industrial areas), you may need to inspect and replace propellers more often.

Choosing the Right Propellers and Materials

The type of propellers you use and the material they are made from can also influence their susceptibility to wear.

- Propeller material: Most drone propellers are made of plastic composites, like ABS or polycarbonate, sometimes reinforced with carbon fiber. While these materials offer a good balance of strength and flexibility, they are not immune to wear. Higher-quality materials might offer better resistance to erosion.

- Propeller design: Some propeller designs might be more prone to specific types of wear. While most off-the-shelf propellers are designed for efficiency and durability, exploring reviews and community feedback on different propeller models can be beneficial.

- Genuine vs. Third-Party: While third-party propellers can sometimes offer cost savings, always opt for reputable brands and ensure they are compatible with your drone model. Genuine propellers are typically engineered and tested to meet specific performance and safety standards.

Environmental Considerations and Flight Practices

How and where you fly your drone can significantly impact the lifespan of your propellers.

- Avoid rough landings: Hard landings or collisions can instantly damage propellers, leading to nicks, chips, and potential deformation. Practice smooth takeoffs and landings.

- Be mindful of takeoff/landing zones: Avoid taking off or landing in areas with loose sand, gravel, or excessive dust. These particles are the primary culprits behind leading-edge erosion. If necessary, use a landing pad.

- Cleanliness: After flying in dusty or dirty environments, gently clean your propellers with a soft cloth to remove any accumulated debris. Avoid harsh chemicals or abrasive cleaning methods.

- Weather conditions: While not directly causing cupping, flying in heavy rain can introduce water droplets that, when impacting at high speeds, can contribute to erosion.

By understanding the aerodynamic principles behind propeller cupping, diligently inspecting your propellers, and adopting a proactive maintenance approach, you can ensure your drone flies efficiently, stably, and, most importantly, safely. Propellers are a consumable component, and treating them as such, with regular checks and timely replacements, is a fundamental aspect of responsible drone operation.